●TWIN HEADS SCREWDRIVING MACHINE

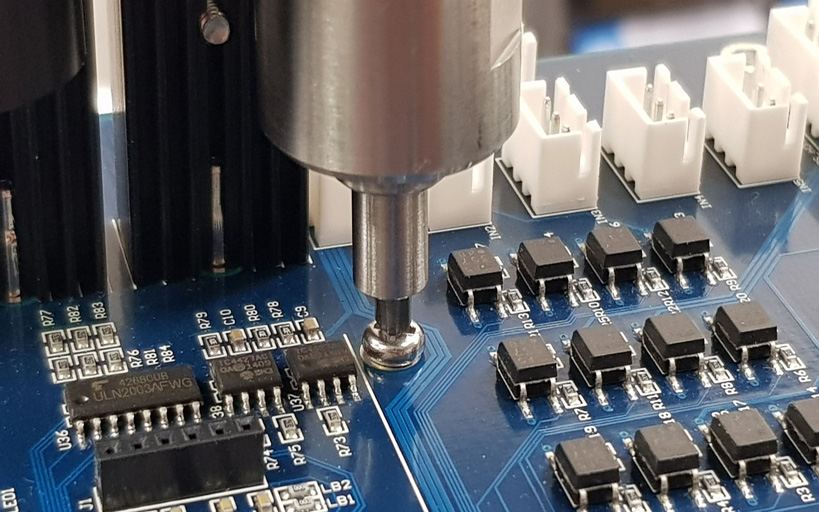

Auto screwdriving robot with intelligent detect function for screw missing, floating screw and stripped screw.

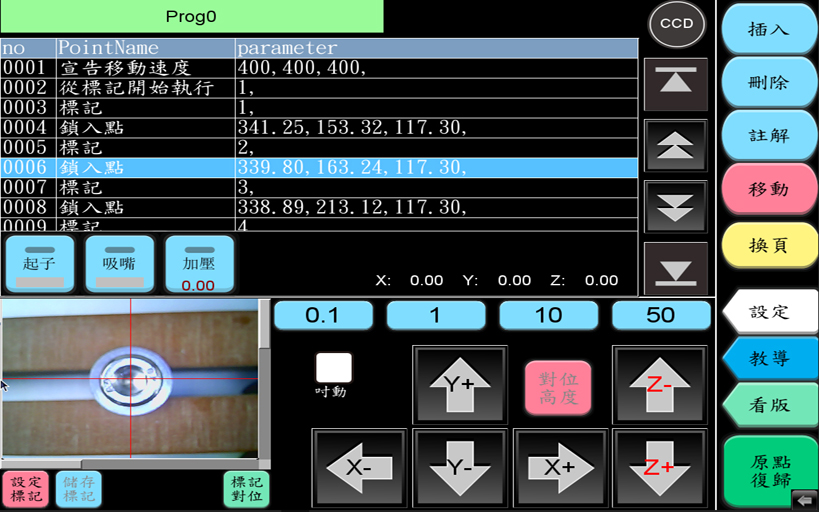

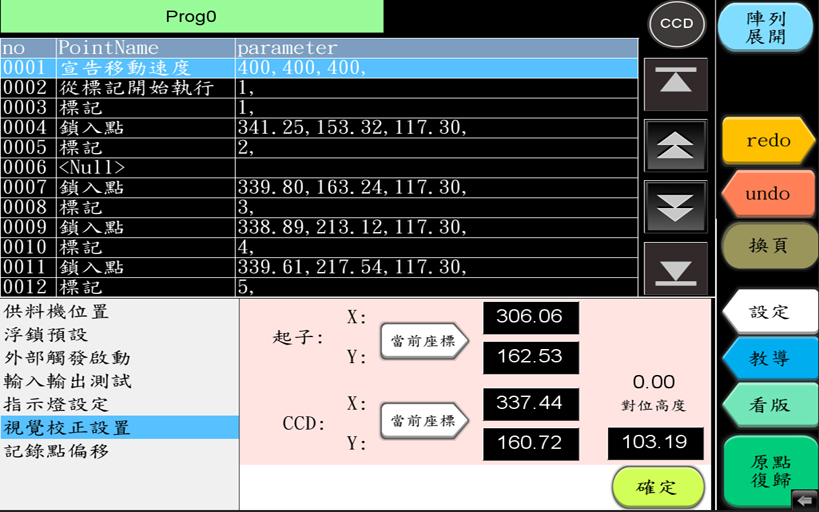

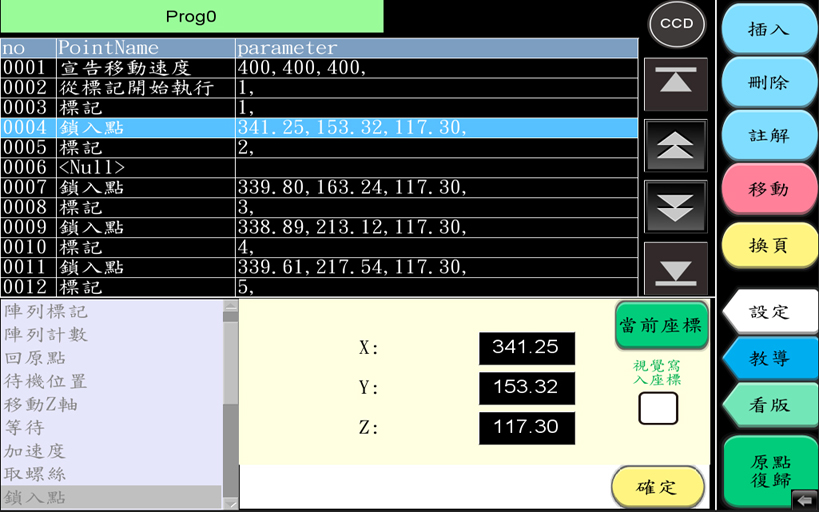

- Easy program editing with Human Machine Interface.

- Optical ruler with coordinate position report function.

- Electric screwdriver with torque detects and warning functions.

- Intelligent detect function for screw missing, floating screw and stripped screw detection.

- Fasten different screws in one machine, to improve production efficiency.

.jpg)

For more examples, please click here

Practical application example

Operating procedures

Vision Alignment System

Parameter Setting

Program Editing

Automate Screw Fasten

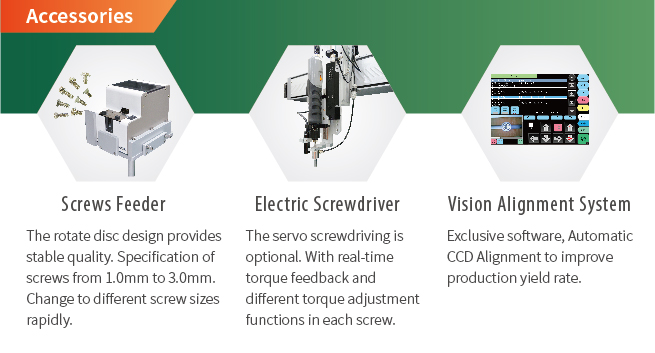

Accessory

Screw feeder

Electric screwdriver

Vision Alignment System

| Moving Area (X/Y/Z) | 700 / 500 / 100 mm |

| Moving Speed (XY/Z) | XY/Z:1000 / 350 mm/sec |

| Data Memory Capacity | 9999 points/prog. 100 programs |

| Display Mode | Human-machine interface |

| Teach Mode | Human Machine Interface |

| Nozzle specification | <9mm (maximum diameter) |

| Screw Length | <18mm (maximum diameter) |

| Working Pressure | 5~7 kg/cm² dry air source |

| Working Humidity | 20-90% no condensation |

| Machine Weight | 121 kg |

| Working Area (X/Y) | X1/X2:500mm / 500mm |

| Repeatability | +/- 0.01 mm/ Axis |

| Data Storage Method | USB/SD card |

| Transmission system | Precision slide guide (MIT) |

| Electric Screwdriver | Brushless DC voltage |

| Screw Feeder System | disc type M1.0~M3.0mm (1.0/1.2/1.4/1.7/2.0/2.3/2.6/3.0) |

| Input Power | 100V~230V / 450W |

| Working Temp. | 10-40°C |

| Machine Size WxDxH | 1200 x 800 x 860 mm |

.png)

.png)

.png)

.png)

.png)